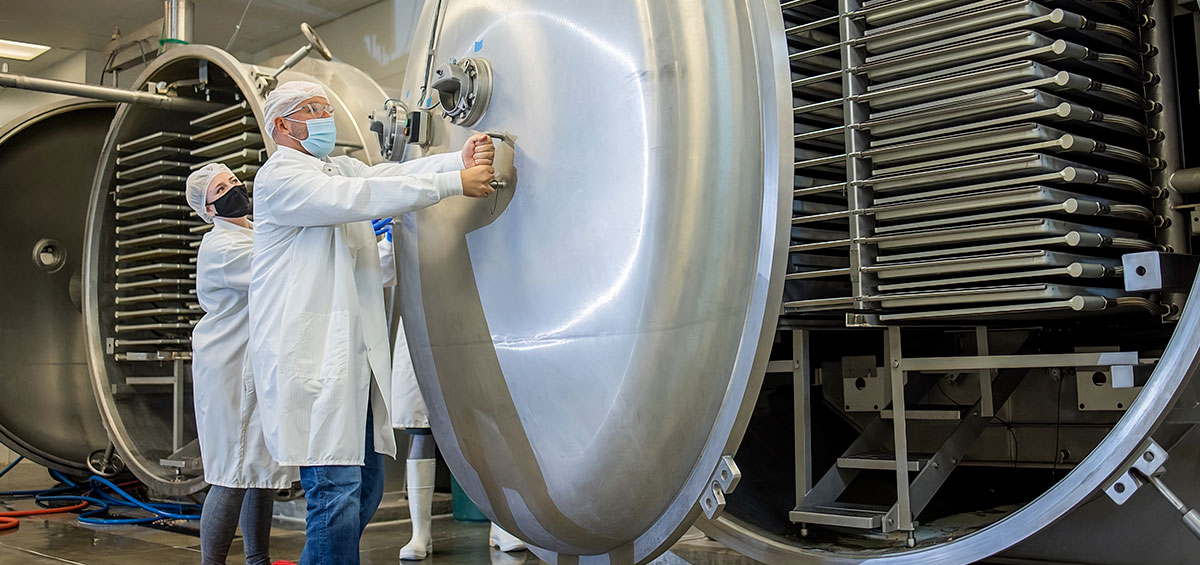

Freeze-drying and quick freezing plant

is the largest in the CIS countries

Freeze-drying is one of the most advanced methods of preservation. Freeze-drying does not require any chemicals or preservatives, and depending on the type of packaging, freeze-dried products can be stored on average up to 5-10 years, and when using special types of packaging — up to 50 years.

FRUTTA freeze-drying Plant is one of the three largest producers of freeze-dried fruits and berries in the world by loading raw materials.

Freezing of vegetables and fruit and berry products has its own characteristics. In order to keep the products as close to natural as possible, a special cold treatment technology is required.

Quick freezing involves exposure to ultra-low temperatures for a short time. Fruits freeze completely and quickly, which favorably affects their appearance and quality. Vegetables and fruits retain their shape, color and nutritional qualities. Individual quick freezing (IQF) chambers with the highest productivity in Central Asia - up to 8 tons/hour.

The freeze-drying process of food products occurs as follows: the product is frozen, then sent to a freeze-drying chamber, where, under conditions of high vacuum and heating of shelves to 40-50 ° C, the process of water transition from a solid state immediately into a gaseous state occurs.

Thus, it turns out to preserve the original shape of the product, all its taste qualities and useful properties, and reduce the weight of the product by 5-10 times. After freeze-drying process is completed, the product is removed from the chamber and sealed.

If a frozen berry is placed in a chamber and the freeze-drying process begins, the moisture contained in it will leave the berry without changing the structure and shape of the fruit itself. At the same time, the berry will retain not only its shape, but also all the nutrients, including vitamins and proteins. This is possible due to the fact that the product is heated during freeze-drying, unlike drying, without overheating, and the product is not oxidized with oxygen in the chamber.

TECHNOLOGY PARTNERS:

The world market leader since 1996 in the highly efficient removal of moisture from food products DEVEX, a member of KAHL group, has its own Innovation Center for development of food freeze-drying technologies in Bremen (Germany). The technology supply map includes all continents in more than 20 countries. Experience in the CIS – the largest coffee freeze-drying plant in St. Petersburg (Russia). DEVEX's largest fruit and berry freeze-drying customers are: Chaucer Foods in Oregon (USA) 48 tons per cycle, Diana Foods (France) 60 tons per cycle, PARADISE FRUITS (Germany) 20 tons per cycle, Otto Suwelack (Germany) 36 tons per cycle.

Views: 1821

Saved: 22.11.2022